Wheels and axles

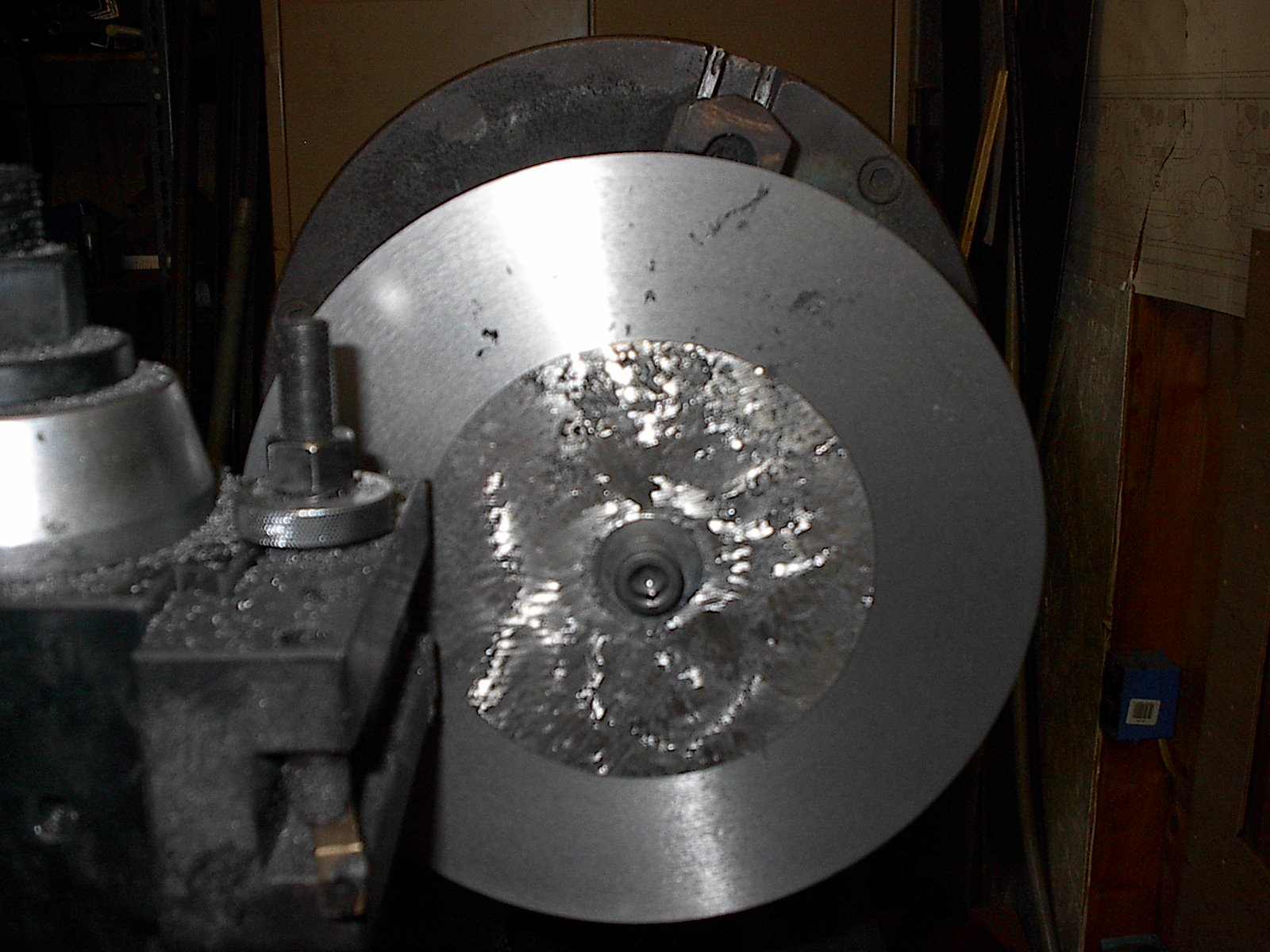

The wheels are cast out of grade 30 cast iron. They were placed in the 3-jaw chuck and the front (outside) faced off and the counterweight set out a little over .25 inch to allow truing after the back was trued and cut to thickness. The axle hole was also reamed before it was removed so that the face was true with the axle hole. Then I placed the wheel on a mandrel to face the back. Then turned it around on the mandrel and finished the thickness .875" and cut the tread

Turning the back I cast them quite thick to allow enough to get all the pits out

The first wheel all that is left is to drill and ream the crank

And cut some out of the back to open up the "spokes"

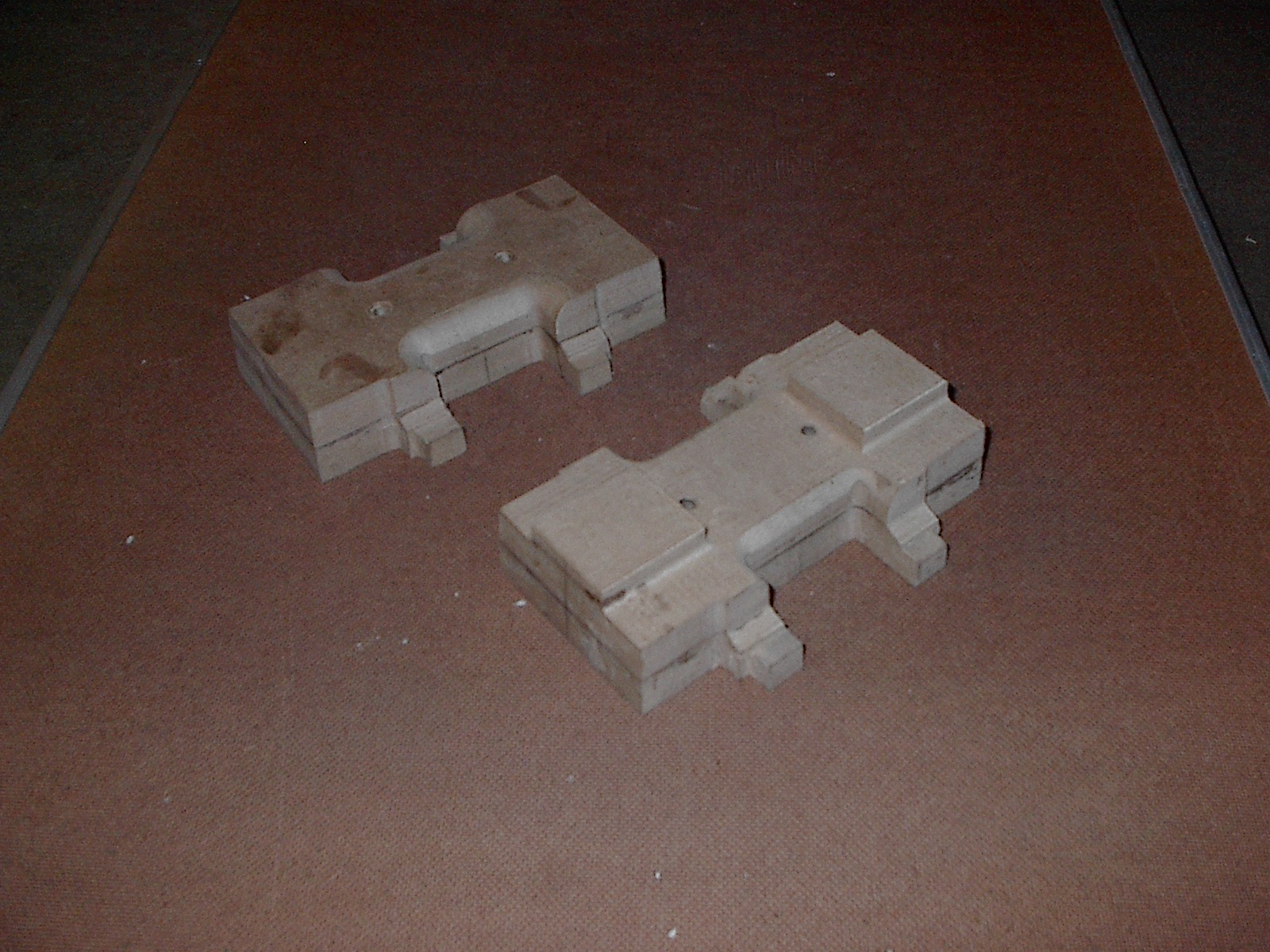

Axle boxes

This is the pattern for the axle boxes they will be cast out of aluminum the first picture is the two halves. I placed half the mold and the pouring cup on a piece of ply and rammed the sand, turned the drag over, removed the ply but left the mold half and cup in the sand , covered it with wax paper pinned the other mold half and runner and rammed up the cope

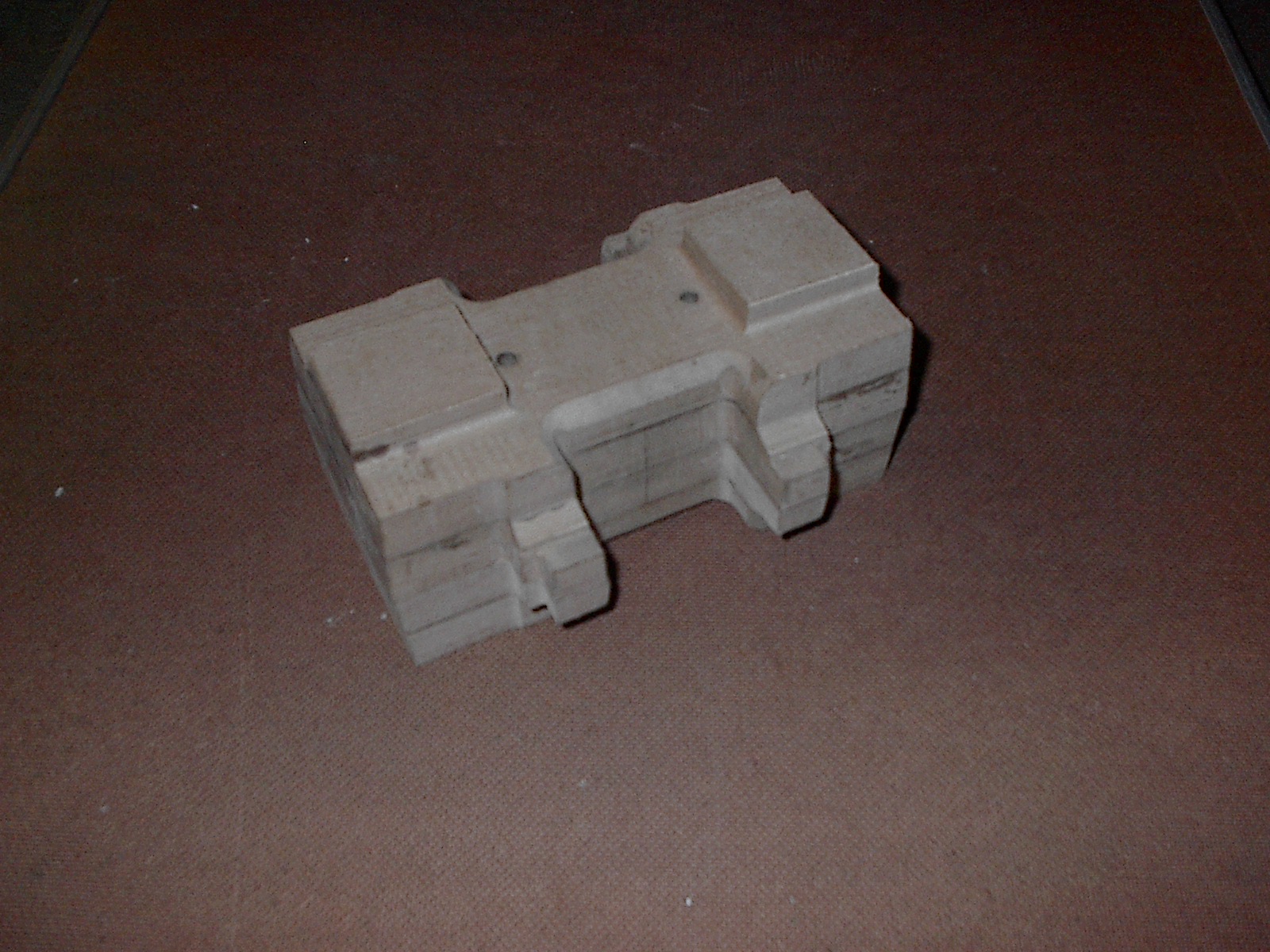

and here is the first box with the pouring cup runner and sprue attached

this is the first axle box . They will have the lateral centering devices as did the prototype.

I am going to have an oil cup in the cab with a pipe running to each axle for gravity feed oiling the bronze bushings